info@bilgergmbh.de

+49 (0)6051 916 69-51

Environmentally and resource-saving method for transformer oil cleaning

The sodium technology is suitable for the dehalogenation of a wide variety of products, although solid compounds can in principle also be treated.

Dr. Bilger Umweltconsulting has had extensive experience in using sodium to decontaminate organic compounds for more than 30 years. This process takes advantage of the extreme reducing properties of sodium.

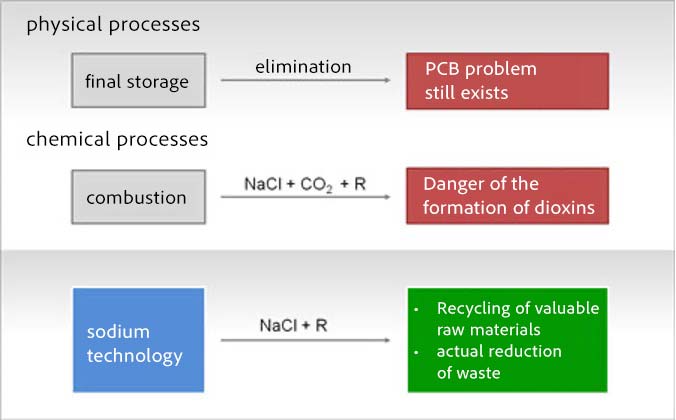

Organically bound chlorine combines with finely divided sodium to form table salt and carbon. As a result, only harmless residues remain that can be easily disposed of.

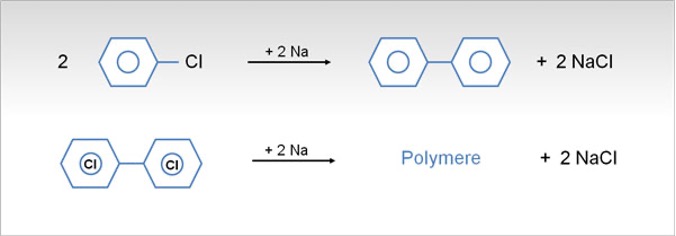

This process takes place at relatively low temperatures (room temperature up to approx. 150° C) in the liquid phase. However, the sodium must be present in a very finely distributed form in order to increase its surface area.

For this purpose, elemental sodium is dispersed in an organic solvent, usually paraffin oil, whereby a particle size of <15 µm must be achieved.

Example of a system for treating 1,000 l/hr. Transformer oil in transit.

© Dr. Bilger Umweltconsulting GmbH

This sodium dispersion is used in sodium dispersion systems manufactured by Dr. Bilger Umweltconsulting has been used successfully for over 30 years.

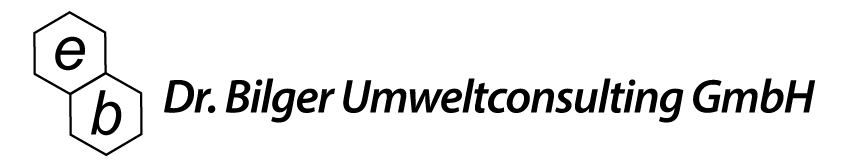

Sodium treatment is the most widely used non-combustion technology to destroy PCBs in oils and other organic solvents.

During sodium treatment, organically bound chlorine combines with finely divided sodium to form table salt and harmless organic compounds. As a result, only unproblematic residues remain that can be disposed of. The amount of residue produced during dechlorination is proportional to the PCB content of the treated liquid.

For oils with a PCB content of 1,000 ppm PCB, for example, the total amount of residue amounts to approximately 1% of the oil weight. In contrast to combustion, the formation of dioxins and furans is completely excluded with sodium technology. There is NO environmental impact through CO2 emissions.

Treatment of landfill leachate oil in Hamburg-Georgswerder

Gewerbepark Birkenhain 7a

63579 Freigericht

Tel: +49 (0)6051-91669-51

Fax: +49 (0)6051-91669-57

E-Mail: info@bilgergmbh.de