info@bilgergmbh.de

+49 (0)6051 916 69-51

Content | Unit | min. | max. |

|---|---|---|---|

Sodium (Na) | % | 18 | 22 |

inorganic carrier | % | 78 | 82 |

size | mm | 3 | 4 |

bulk density | kg/L | 0,7 | 0,7 |

SOLVONA® (Sodium content: approx. 20 G%) is supplied as standard in glass bottles with a capacity of 250 ml, 500 ml, 1000 ml and 2000 ml.

250 ml (175g)

500 ml (350g)

1,0 L (700g)

2,0 L (1400g)

in laboratory glass bottles with graduations (under argon)

method | % | |

|---|---|---|

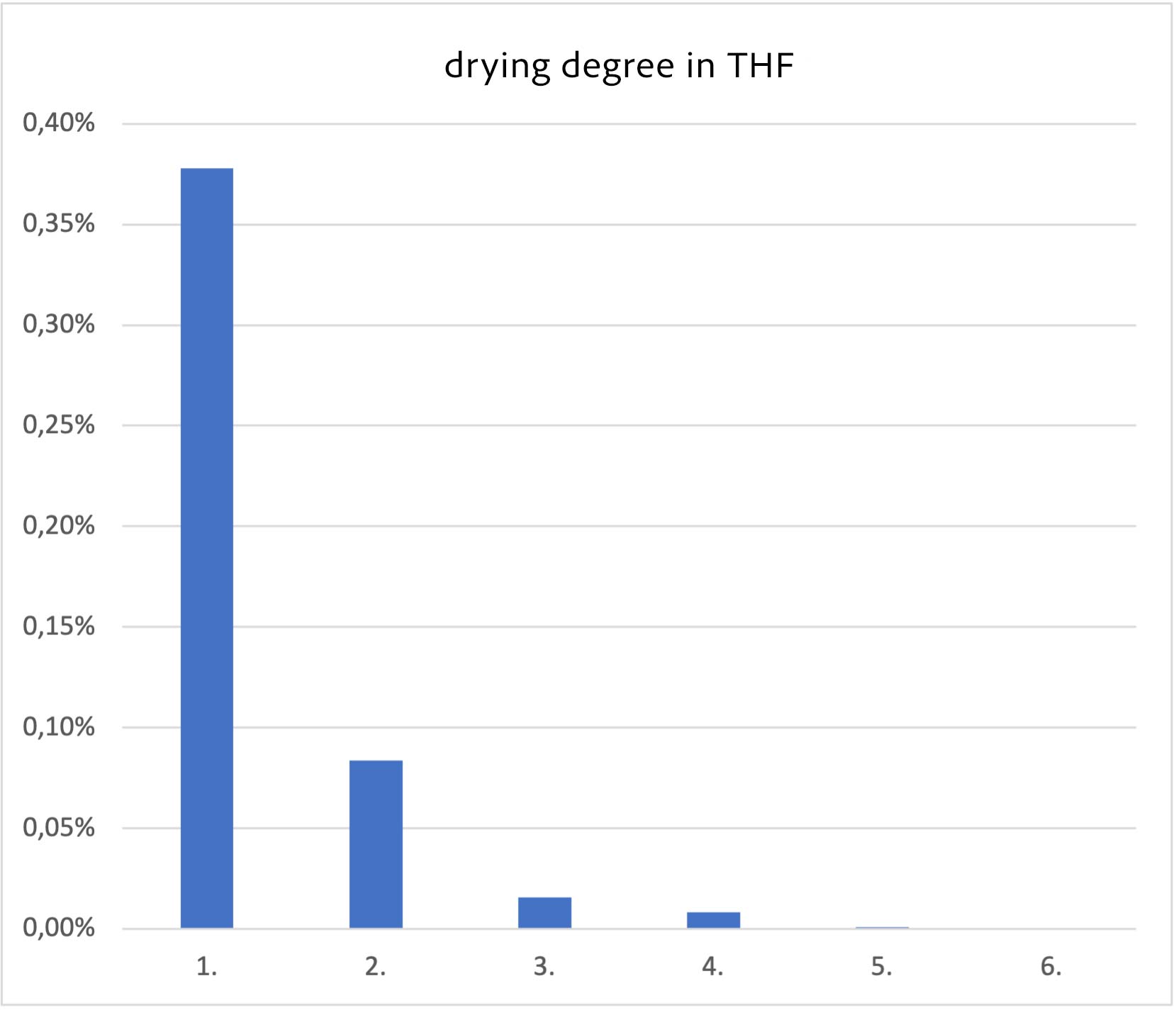

1. | THF from stock | 0,38 |

2. | THF dried with KOH | 0,0838 |

3. | THF dried with CaH2 | 0,0156 |

4. | THF dried with K | 0,0084 |

5. | THF 0,5h dried with SOLVONA | 0,0009 |

6. | THF 1,0h dried with SOLVONA | 0,0001 |

Practical examples of solvents to be dried with SOLVONA® are:

SOLVONA® should only be used in steel, stainless steel or glass containers. When working with SOLVONA®, suitable gloves and safety glasses with side protection must be worn.

The sediment should be approx. 2 cm high. Since the reagent also functions as an indicator, you can see how much the material has been used up by the discoloration of the pellets.

To ensure effective and efficient drying with SOLVONA®, we recommend storing in the solvent to be dried. Capacity losses caused by excessive contact with air are avoided and a constant supply of dried reagent is ensured.

SOLVONA® guarantees you excellent drying up to an almost uniform white color. Used, smaller amounts of SOLVONA® can be carefully added to low-boiling alcohols (e.g. isopropanol) in smaller portions. The resulting alcoholate can be destroyed by slowly adding water and must then be disposed of in accordance with waste code no. 160503.

1000 g of SOLVONA® bind approx. 100 g of water.

SOLVONA® must be stored protected from air ingress and moisture. It should not be stored in close proximity to highly flammable substances. If stored properly under argon, SOLVONA® can be stored unopened for at least two years.

See also:

After several incidents involving sodium/potassium dried solvent distillations, particularly tetrahydrofuran, occurred at the university, the use of sodium and/or potassium as drying agents was banned. So SOLVONA® was found as an alternative, which is easier and safer to use. And yet we achieve very good results when it comes to drying our solvents.

The reagent SOLVONA® was developed to dry heat transfer oils effectively and without a lot of time. Heat transfer oils are used, among other things, to operate wind tunnels in the automotive industry.

Since these systems are exposed to extreme temperature fluctuations (-50 to +60° C), absorption of moisture by the heat transfer oil must be avoided under all circumstances.

In practice, when using heat transfer oils, moisture is absorbed from the atmosphere due to leaks in the system as well as the so-called breathing of open systems via an expansion tank. This leads to problems, especially if the oil is to be used at temperatures of <0°C.

From a certain water content (> 100 ppm) the water freezes. In circuits in which oil is pumped, this leads to pumps blocking.

The failure of the circuit cannot then be prevented. In order to keep the heat transfer oils dry despite the weak points mentioned, it is advisable to integrate a drainage unit into the oil circuit or to use a drying system during maintenance breaks. SOLVONA® has a water absorption capacity of approx. 10%.

This means that costs for maintenance work can be significantly reduced.

Gewerbepark Birkenhain 7a

63579 Freigericht

Tel: +49 (0)6051-91669-51

Fax: +49 (0)6051-91669-57

E-Mail: info@bilgergmbh.de