info@bilgergmbh.de

+49 (0)6051 916 69-51

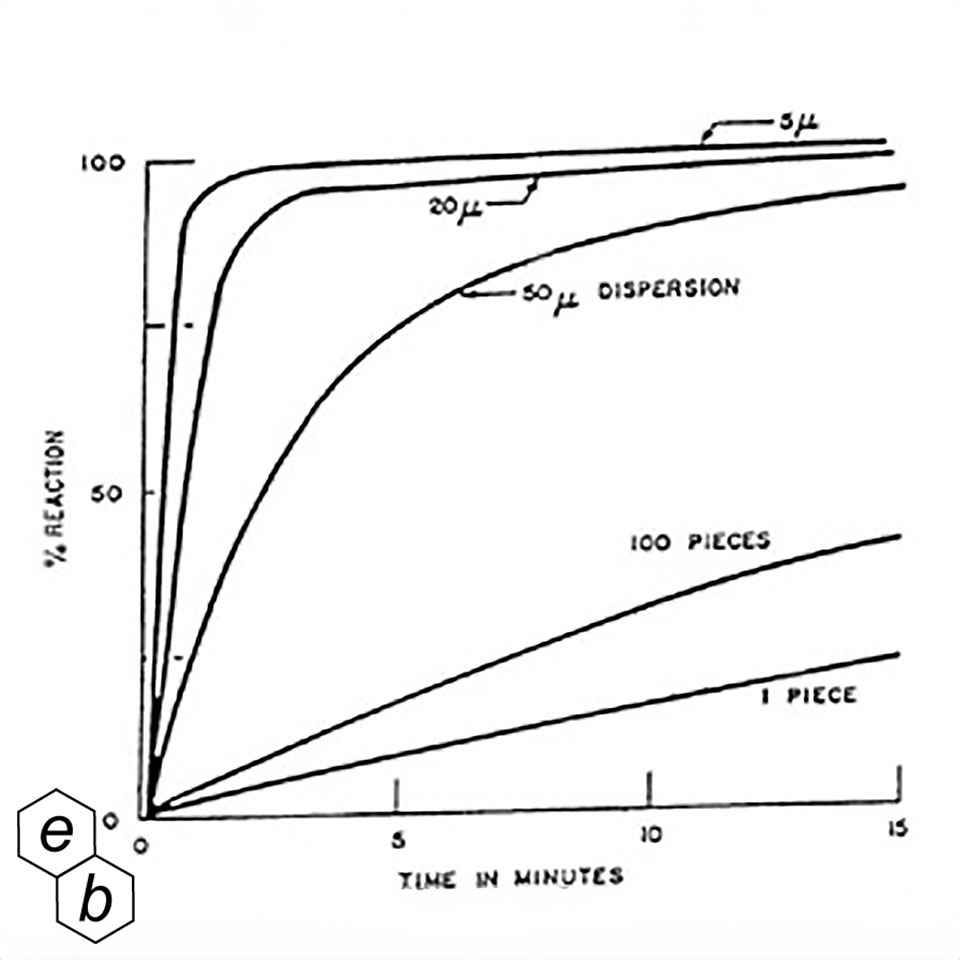

The reaction rate depends on the temperature but also on the form of the sodium used. The graphic shows the influence of particle size on the reaction rate.

1kg sodium as a cube with an edge length of 10 cm: 0.06 m² as a dispersion with particles of 5 µm: 1200 m²

(Source: Fatt – Tashima, Alkali Metal Dispersions, 1961, p.119)

Sodium dispersion finds attractive use in organic synthesis because of the extremely high surface area of the reactive metal.

In reactions with sodium below 98 °C, the metal is present heterogeneously in the reaction medium. In order to increase the surface area, which is crucial for the reaction rate, sodium is dispersed in inert solvents or oils above its melting point using a high-quality dispersing unit.

The advantages of a dispersion include: E.g.:

Examples of beneficial uses of dispersion include:

HALEX® can be stored indefinitely under correct storage conditions. There must be no open water points or pipes carrying water in the storage rooms. Sprinkler systems are not permitted.

See also this:

Gewerbepark Birkenhain 7a

63579 Freigericht

Tel: +49 (0)6051-91669-51

Fax: +49 (0)6051-91669-57

E-Mail: info@bilgergmbh.de